Ershigs (a division of Denali, Inc.)

Ershigs, Inc. is a progressive and innovative leader in design/engineering, manufacturing, fabrication, and installation of corrosion-resistant equipment and systems of fiberglass reinforced plastics, FRP.

The company serves numerous industries, including: Power/FGD, Pulp and Paper, Metals and Mining, Chemical Processing, Industrial Water and Waste Water, and Semiconductor. Ershigs’ custom FRP products include shop tanks, piping, StoplineTM abrasion resistant piping, ductwork, process vessels, and stacks. Ershigs is the leading North American supplier of field wound FRP chimney liners, ductwork, scrubber shells, and field tanks used in FGD service and other industries. In addition to the corrosion industries served by Ershigs FRP Division, Ershigs Metal Division provides a range of steel pipe supports and custom fabricated steel, stainless steel, and aluminum products and installation for industries to include marine, food service, and architecture.

The Ershigs organization operates with four manufacturing plants located in Bellingham, Washington; Grand Bay, Alabama; Ridgefield, Washington; Iuka, Mississippi. In addition, Ershigs is a recognized Specialty Contractor with mobile FRP field winding operations and the capability and experience in managing onsite construction and manufacturing projects.

Chemical Service and Water Service Piping

Ershigs designs, manufactures and installs custom FRP Piping systems for a wide range of configurations and conditions to include:

– Sizes range from 1”ID through 168”ID

– Full range of flanges, reducers, elbows and fittings

– Filament wound, contact molded and infusion construction

– Pressure ratings from 25 psig through 250 psig

– Full vacuum

– Above ground and below ground applications

– Joint configurations include butt and wrap, adhesive, flanged, Vanstone style flange, O-ring bell and spigot

– Ershigs E-Lock O-ring bell and spigot joint with internal locking ring

– Anchors, hangers and supports (reference our metal division page)

– ANSI/NSF-61 Certified piping 10”ID through 72”ID

– ANSI/NSF-61 Certified well casing 10”ID through 72”ID

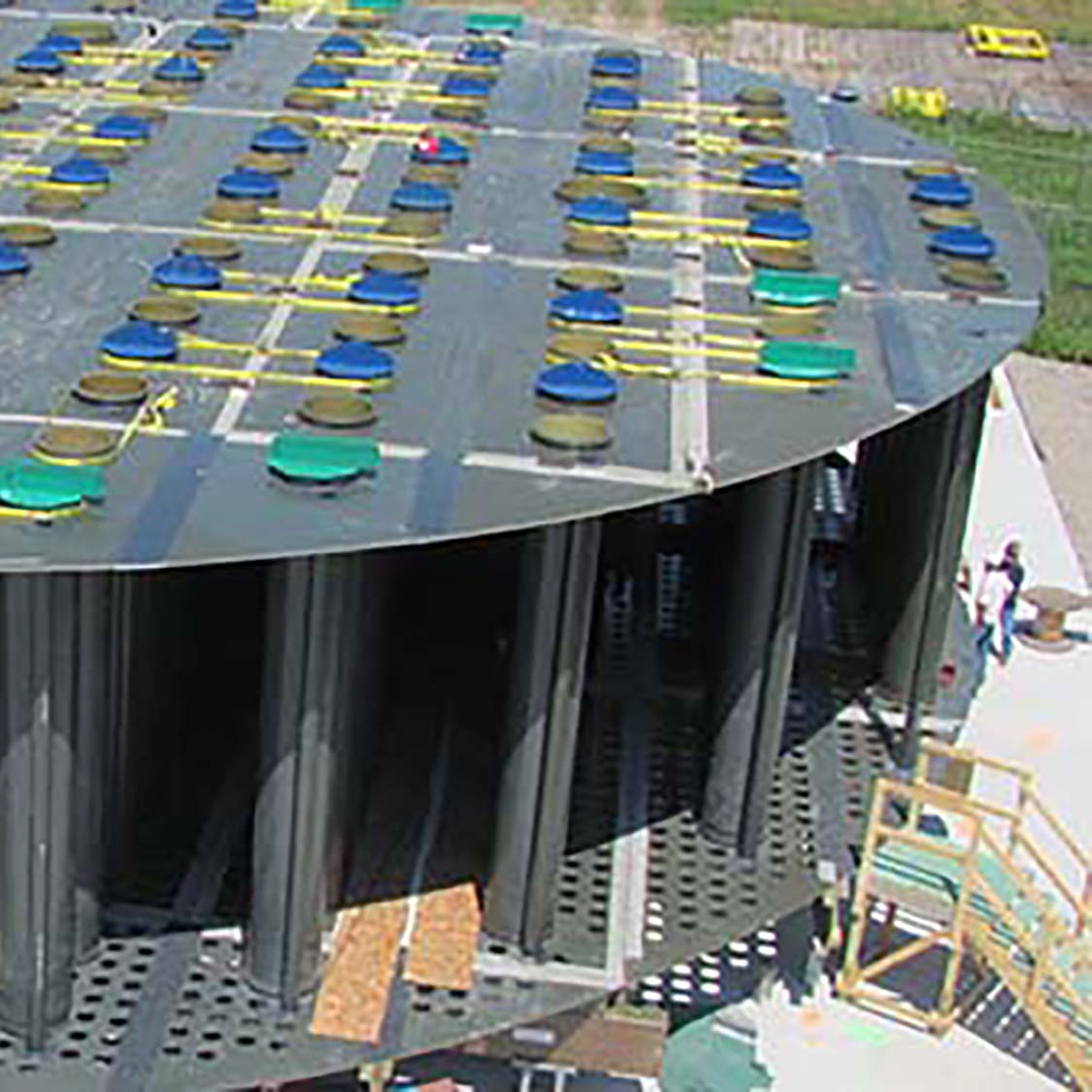

Scrubbers

Industrial scrubber/absorber, shells and vessel internals have been manufactured using FRP for many years due to the corrosion resistance and dependability of Fiberglass Reinforced Plastic .

Ershigs FRP scrubbers and scrubber components have been used in a wide range of industries to include Power & FGD, Metals & Mining, Chemical Processing, Cement, Water Remediation and Odor Control.

With the proper material selection, FRP can provide long term corrosion resistance and low maintenance costs in applications where carbon steel, stainless steel, duplex stainless steel, coatings, linings are simply not a long term solution. FRP material is also a more economical solution to high-nickel content alloys in scrubber environments containing elevated chloride concentrations or wet acids.

Ershigs engineering team works with your process design team to develop a structural design and configuration for scrubbers and strippers ranging from shop sized vessels up to 18 feet in diameter and large field sized scrubbers up to 120 feet in diameter. Our methodology streamlines the project development process, improves coordination, and results in precisely engineered projects. Ershigs’ results are proven in hundreds of major projects across a wide variety of industries.

With Ershigs five manufacturing facilities in the U.S., Canada and a Field Construction division, we provide regional service and support. Whether we are asked to manufacture scrubbers on-site or to install shop manufactured scrubbers, Ershig’s experience in construction and planning makes the installation more efficient and trouble free.

Unique in the industry, Ershigs’ on-site fabrication process overcomes size constraints and difficult access issues – and we provide highly cost-effective results when many large components are needed at a remote location. With twelve mobile field winding operations and a full specialty construction division, our team works virtually anywhere in the world on your important projects.